If you’ve ever worked on a shared drive full of CAD files, you’ve probably run into the same headaches many engineers face: overwritten designs, duplicate revisions, broken references, or worse, hours of rework because the wrong file was used. These problems only grow when teams get larger, projects become more complex, and deadlines tighten.

That’s where SOLIDWORKS PDM (Product Data Management) comes in. PDM is more than just a place to store files, it’s a system for controlling, organizing, and collaborating on design data. Whether your team is just getting started with PDM or looking to establish stronger habits, the following best practices for file management, collaboration, and revision control will help you get the most out of your system.

File Management Best Practices

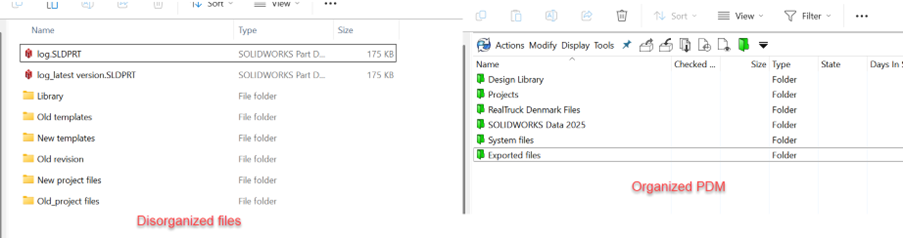

Structure Your Vault Wisely

The first step to effective PDM use is setting up a logical vault structure. Resist the urge to create a single “catch-all” folder for everything. Instead, organize data by project, customer, or product line—whatever makes sense for your business.

SOLIDWORKS PDM allows you to create folder templates, which can automatically build a consistent structure each time a new project starts. For example, every new project might automatically include folders for CAD, drawings, manufacturing files, and quality documentation. This prevents chaos and ensures everyone knows where to look.

Use Metadata, Not Just File Names

A common trap in unmanaged environments is cramming details into file names: Bracket_V2_Approved_Final_FINAL.SLDPRT. PDM solves this with metadata properties—fields like description, part number, material, or revision level.

By filling out these properties, you make files searchable without relying on complicated names. Need to find all aluminum brackets designed for a customer last year? Metadata makes it possible with a few clicks.

Tools like the Property Tab Builder can help standardize how users enter information, reducing errors and keeping data clean.

Automate Where Possible

Automation is one of PDM’s strongest features. Instead of relying on users to remember every step, you can:

- Auto-generate part numbers.

- Use templates to pre-fill drawing borders.

- Create standard folder structures.

Not only does this save time, it also enforces consistency across the company.

Collaboration Best Practices

Check-In and Check-Out Discipline

The check-in/check-out system is at the core of PDM collaboration. When a file is checked out, only one person can edit it, while others can still view and use the latest version. This prevents overwriting and ensures accountability.

Encourage your team to develop a habit: check in files at the end of the day. Not only does this make the latest work available to colleagues, it also ensures backups are created in the vault.

Define Clear Roles and Permissions

Not everyone should have the same access. SOLIDWORKS PDM allows administrators to set permissions so that users can only see or edit what’s relevant to them. For example:

- Engineers can edit CAD files but not release them.

- Managers can approve files but not modify them.

- Shop floor users can view released drawings but not edit designs.

This principle of “right people, right access” keeps data secure and reduces the risk of accidental changes.

Support Remote and Multi-Site Teams

For organizations spread across locations, PDM Professional offers file replication so that local offices can work quickly with cached copies of files. This ensures that teams in different time zones or regions don’t suffer from slow data access. Combined with PDM’s powerful search tools, engineers can find the files they need quickly, no matter where they’re located.

Revision Control Best Practices

Standardize Your Revision Scheme

One of the most common sources of confusion is revisions. Should you use letters? Numbers? Both? The answer matters less than being consistent.

SOLIDWORKS PDM allows you to define revision schemes that automatically increment when files are approved. Whether your company uses A, B, C or 1, 2, 3, the important thing is that everyone follows the same system.

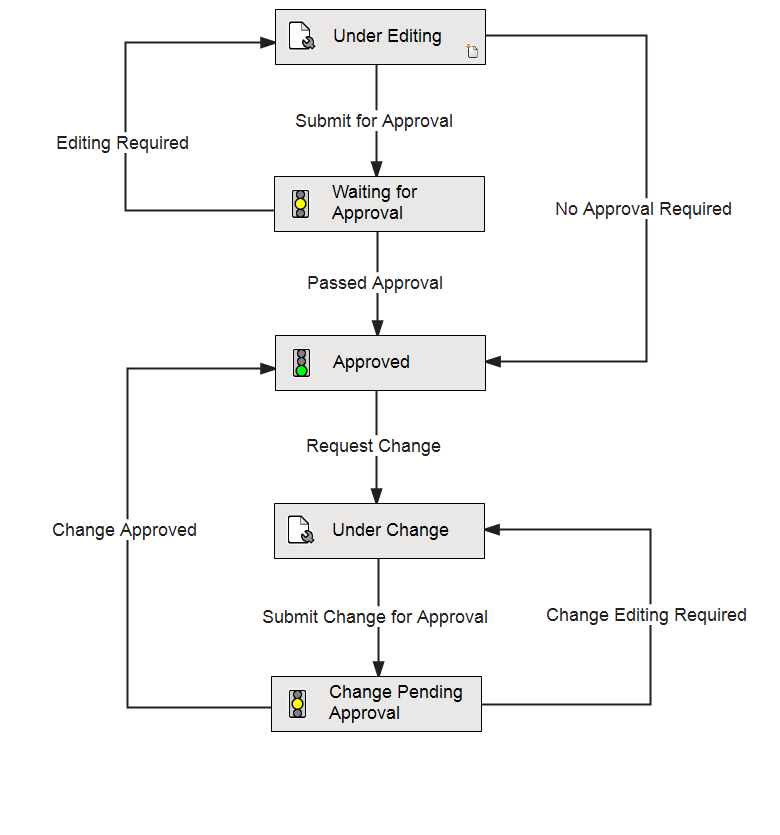

Leverage Workflows for Approvals

Workflows are where PDM really shines. They allow you to automate the path a file takes from design to release. For example:

- Engineer creates and checks in a new part.

- File moves to “Pending Approval.”

- Manager reviews and approves.

- Revision updates and the file is released for manufacturing.

Notifications can alert the right people at each step, reducing bottlenecks and ensuring accountability. The key is to tailor workflows to your company’s actual processes, not the other way around.

Maintain Traceability and Audit Trails

Every action in PDM is logged: who changed what, when, and why. This audit trail is invaluable for industries that require compliance documentation, but it’s also useful internally. If something goes wrong, you can always trace back to the source and recover older versions.

Common Pitfalls (and How to Avoid Them)

- Skipping training: If users don’t understand PDM, they won’t trust it. Invest time in training and establish clear guidelines.

- Poor vault setup: A messy vault creates frustration. Take the time to design folder structures and workflows that fit your business.

- Overcomplicating workflows: Start simple. You can always add complexity later as the team matures.

Takeaway

SOLIDWORKS PDM is more than a digital filing cabinet. When used well, it’s a powerful tool for managing engineering data, preventing mistakes, and streamlining collaboration. By following best practices for file management, collaboration, and revision control, teams can avoid common pitfalls and ensure that their data management system works for them—not against them.

Whether you’re just rolling out PDM or looking to refine your current setup, remember: good habits paired with PDM’s features lead to smoother projects, stronger collaboration, and fewer late-night “which file is the right one?” conversations.