The Word of Day One at SolidCAM World 2025

Wow, what an electric start! Day One of SolidCAM World 2025 in Prague wasn’t just a conference. It felt like a massive family reunion powered by titanium-grade ambition. The energy surged through the Cubix venue from Monday morning. Partners, resellers, and employees were trickling in from all over the world. This gathering was more than just people coming together. It confirmed that this community—this “one big family”—grows stronger every year.

The General Session was pure inspiration, setting the thematic bar high. We heard from Linda, Emil S., and Natalie S., who didn’t just talk numbers; they shared the heart and soul of SolidCAM, confirming that we are not just in the CAM business, but we are building the future of digital manufacturing, brick by highly precise brick.

Linda’s Perspective: The Drive to Be Number One

Linda Somekh took the stage first, radiating warmth and excitement. She quickly established the central theme of the entire company, tracing it back to the passion of SolidCAM President, Emil Somekh.. This isn’t just a company focused on profit; it’s a company born from a singular, lifetime obsession: to be number one, always.

A Story of Dedication

To illustrate this, Linda shared a wonderful, almost unbelievable story from Emil’s childhood. When he was just seven years old, at his own birthday party, “He left because he remembered he had to study for a test”! That level of dedication didn’t stop there. Linda detailed his academic journey through high school where, incredibly, every subject was taught in three languages: Arabic, French, and English. Imagine trying to ace geometry in three languages—yet Emil didn’t just succeed, he was the first in his school and the first in all of Iraq. He went on to secure his BA, MA (Suma cum laude, naturally), and his doctorate.

SolidCAM’s DNA: Excellence from Day One

When SolidCAM was established, this intense drive was immediately infused into the DNA of the company. Linda, who was one of the first employees alongside Emil and Dono Sranski, recalled that Emil’s first priority was never about making “loads of money” (though profitability is obviously necessary); it was always about making SolidCAM the number one software. The core mandate? The software must be easy to learn and to use and must constantly keep developing.

Linda took us down memory lane, highlighting the milestones: M25, M3D, HSM, followed by the revolutionary moment that created “a huge ripple in the world” – iMachining. We then saw the subsequent advances: iMachining 3D, simultaneous five-axis, advanced Milturn, and Swiss. And now, the highly anticipated “newcomer” is Solid Shop, complemented by the AI-powered Chatbot.

The message was crystal clear: being associated with Emil and SolidCAM means being on the winning team. It means we are going to become number one and we “will capture more than 10% of the market”.

Global Recognition and Trust

Linda reflected on the dramatic shift in the industry. SolidCAM has reached a point where we no longer chase partners—“Today everybody comes to us.” She highlighted the incredible trust major global players place in SolidCAM, including SpaceX (yes, Elon Musk’s company), manufacturers of Iron Dome parts, Kaioera, Facebook, Amazon, Mitsubishi, and Airbus.

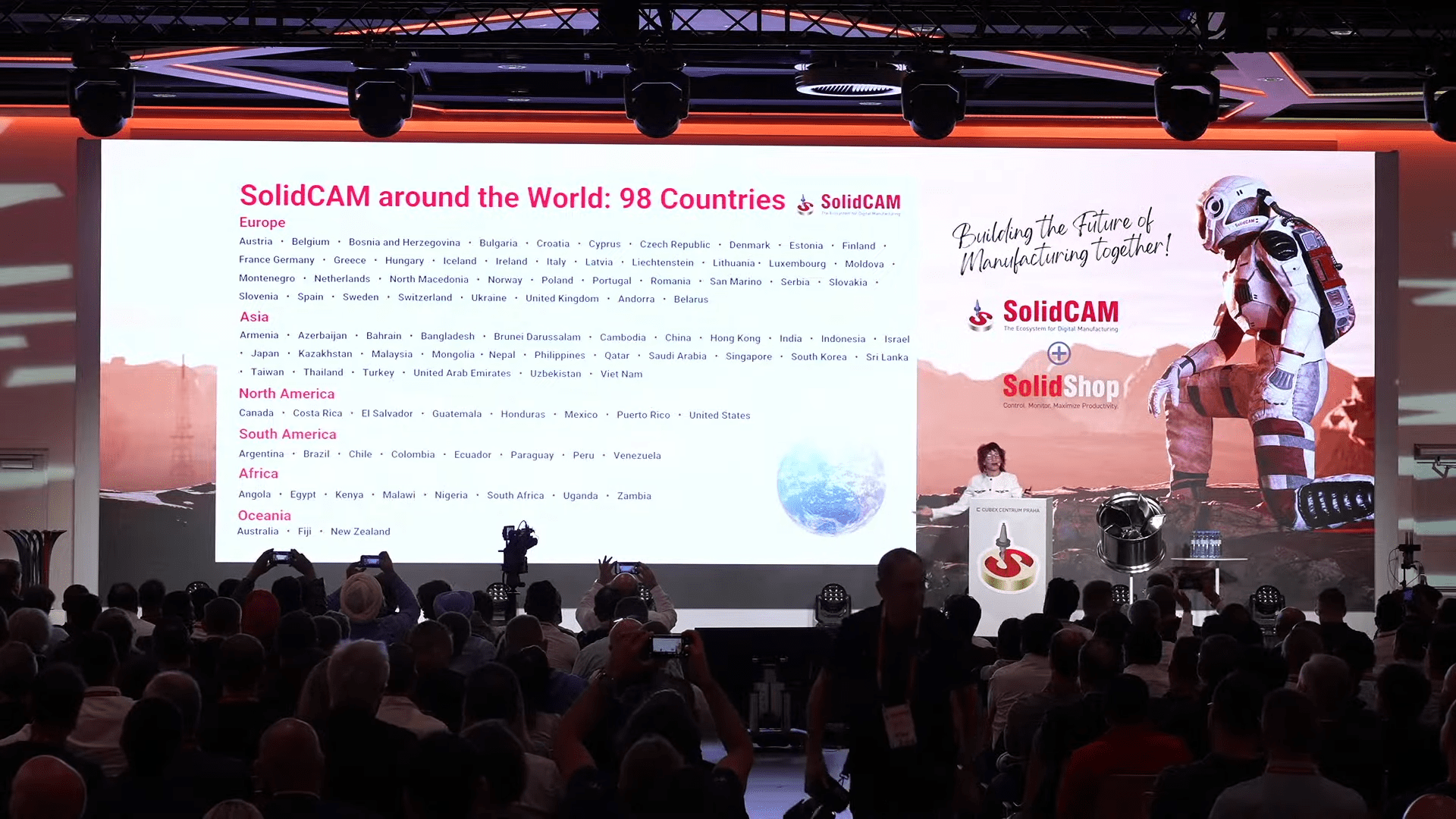

She paused to sincerely thank the resellers, partners, and employees, recognizing their “passion” and effort in making the company great. Then came a truly exciting reveal that underscored our global dominance: we asked the crowd how many countries we operate in (guesses ranged from 32 to 70), and the correct number was a resounding 98 countries! We have customers across every single continent: Europe, Asia, North America, Africa, and Oceania, and that number is constantly growing.

Gold Standard in CAM

After 41 years in business, Linda confidently asked the audience, “Do you all agree that SolidCAM is today the gold standard in CAM?” The room’s response said it all.

Linda also highlighted her passion project, Linda’s Corner, a podcast she started about a year and a half ago. Passionate about connecting with others, she enjoys talking to people and hearing their stories.

She then kicked off the famous giveaway, presenting the first Titanium Pen to the event organizer, Ivan Simmer. The pen was designed in SolidWorks and manufactured using our own Swiss-type solution.

Emil S.: From 256 Slides to the Pillars of CAM Leadership

The moment Emil S. took the stage, he engaged the audience with a joke about his long lectures.

He admitted he chose the shorter version—102 slides instead of 256—but warned it would still take at least an hour. The focus then shifted from inspirational history to the strategic reasons behind the company’s success, all rooted in its “powerful core values.”

Integrated CAM: A Strategic Choice

Emil explained the fundamental decision he made early on: to concentrate only on CAM. While SolidCAM originally had its own CAD system, the Solid Modeler, Emil realized that splitting development power between CAD and CAM meant failing to be the best in either.

This led to our unique, successful architecture where the CAM functionality exists as a full library, linked to various host CAD systems via a bridge. The massive advantage is synchronicity: if anything changes in the CAD, “all the integrations get changed in the same time”. This is why we have the seamless, associative, gold certified integration in SolidWorks, the world’s leading CAD system. When the SolidWorks model changes, the toolpath automatically updates—a critical feature that separates us from competitors who struggle when importing models.

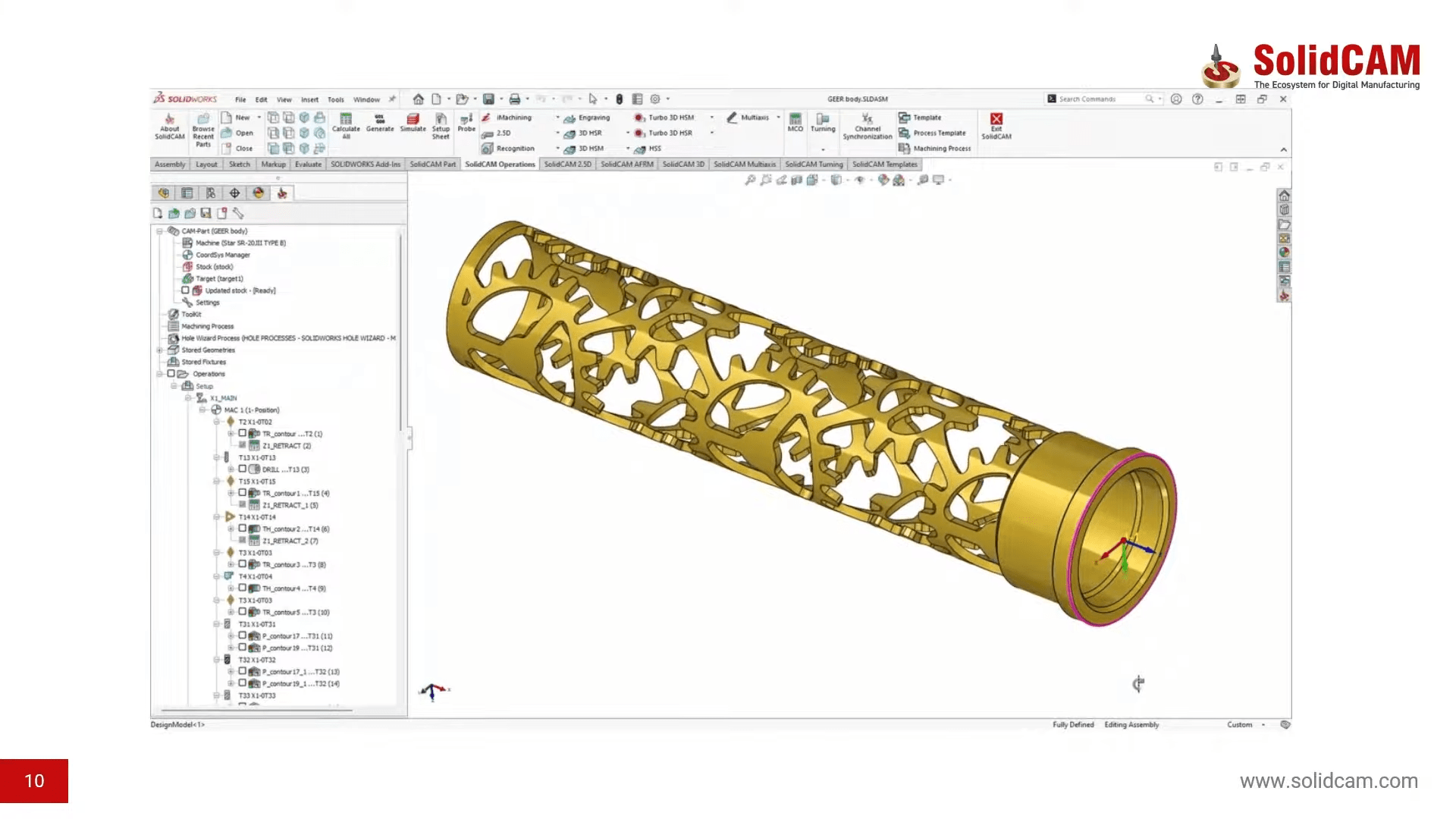

Today, SolidCAM is truly a single CAM solution for all CNC machines, covering 2.5D mill, 3D mill, five-axis, turning, Mill-turn, wire EDM, and probing. But Emil stressed our trademark: the best support for multi-channel Mill-turn and Swiss CNCs.

Partnerships: The Power of Cooperation

Emil’s second core value is clear: “We never reinvent the wheel”. We integrate modular technology from experts. He highlighted our decades-long relationship with Dr. Yavas of Model Works, starting in 2003 with machine simulation and simultaneous five-axis. Due to this close cooperation, Model Works (now employing 400 people) gives us new technologies first, even though they develop for our competitors.

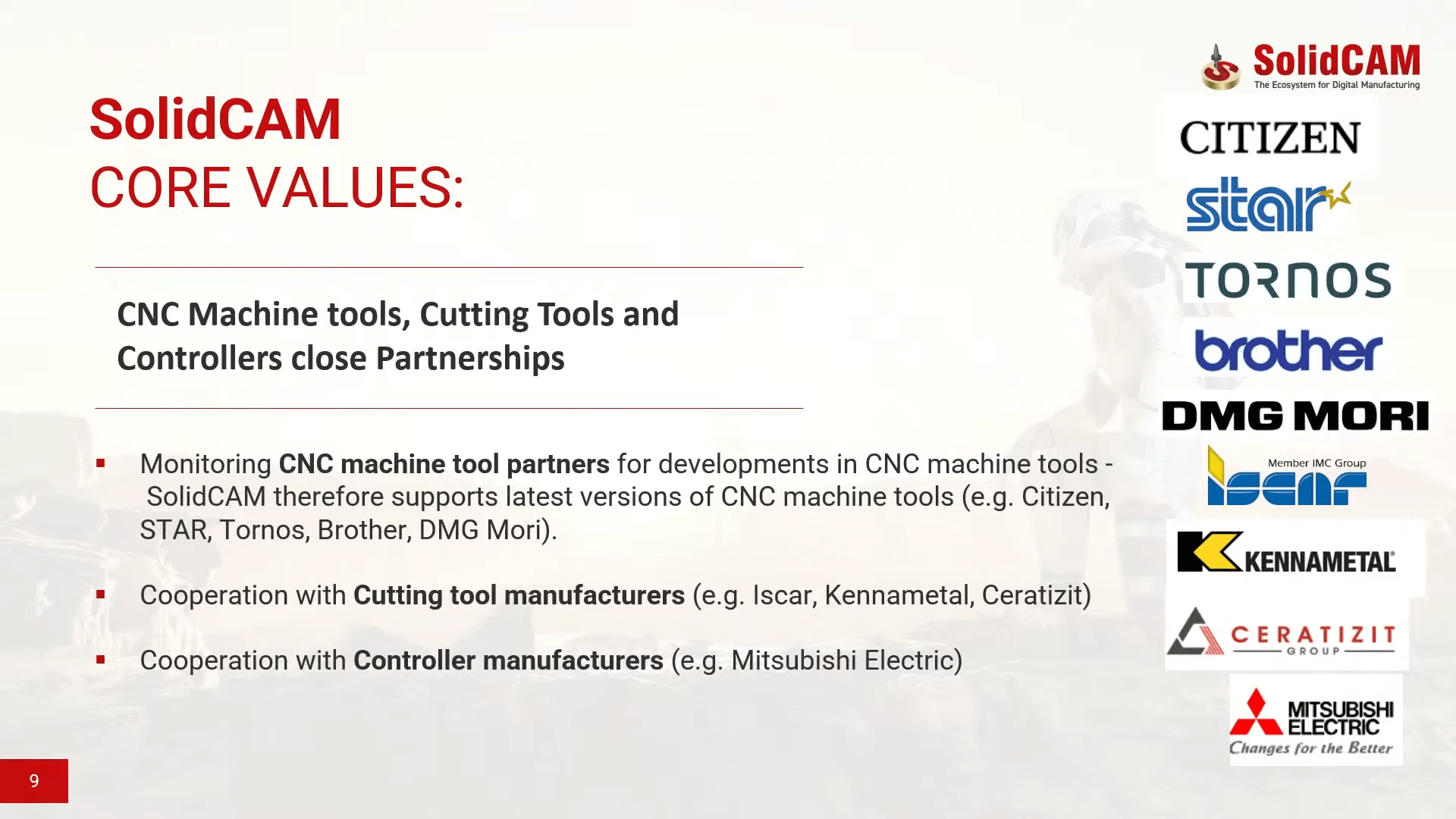

Collaborating with Machine Tool Manufacturers

We also work closely with machine tool manufacturers. Emil mentioned Citizen and Star, noting their relationships began in Germany and expanded to their corporate headquarters. We are a DMQP partner with DMG Mori, leading to involvement in cutting-edge projects like machining the titanium rib launched at EMO.

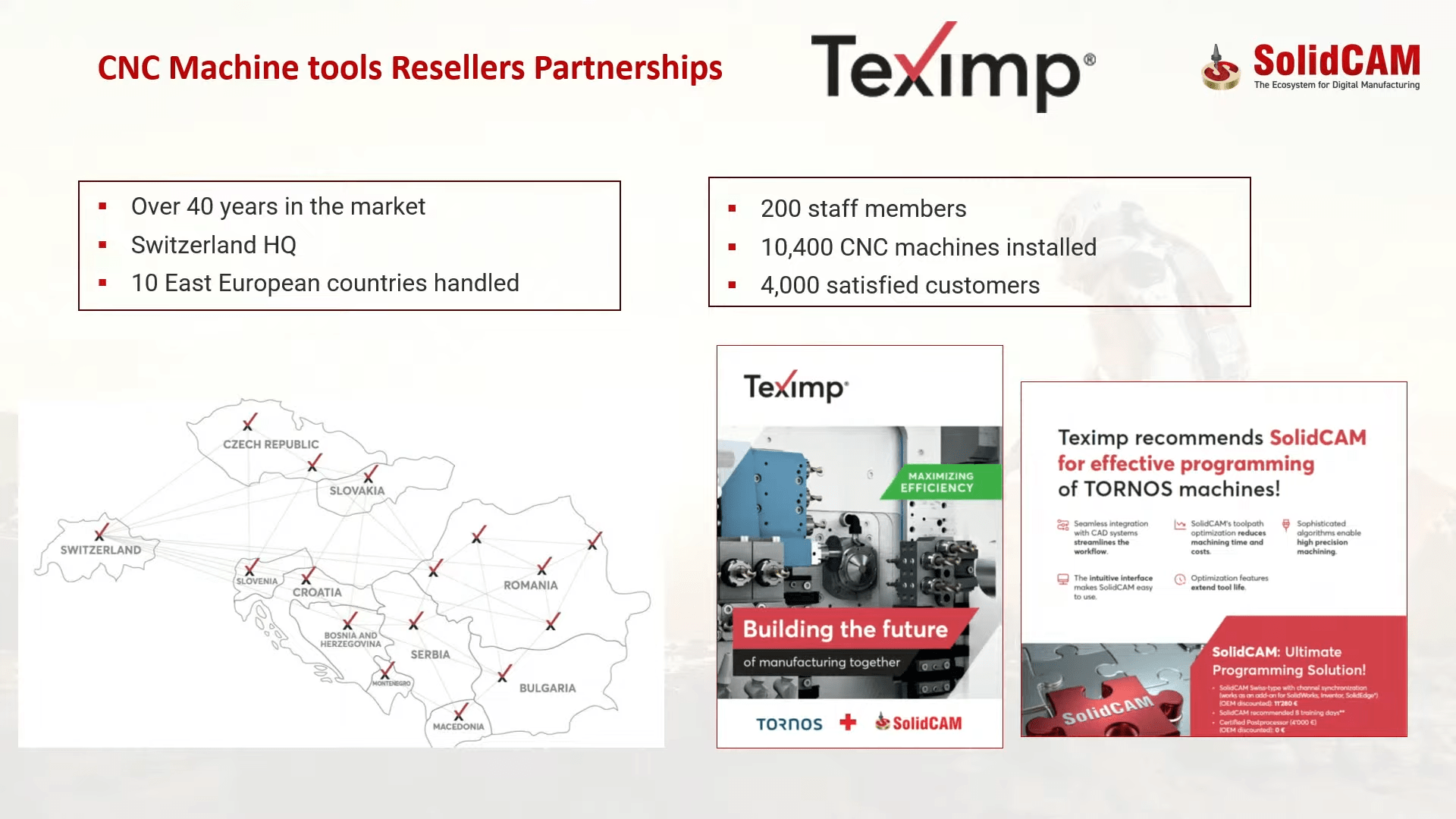

A particularly interesting relationship is with Teximp, a major machine tool reseller in seven Eastern European countries.

After their previous competitor’s support failed, Teximp switched to SolidCAM. This created a strong partnership: Teximp sells the machines, while our local resellers provide the essential software support.

Cutting Tool Partnerships

On the cutting tool side, we partner with ISCAR, allowing direct access to tool data. In the US, we run a joint marketing effort: customers returning to subscription receive a $1,000 voucher for ISCAR tools.

We also partner with KENNAMETAL and Saratis (for dynamic turning tools).

Titans of CNC: Education and Growth

Emil then detailed the high-profile relationship with Titans of CNC. This partnership began because Titan needed CAM support for Tsugami Swiss machines that his existing software couldn’t handle. We started by jointly creating the fantastic, free Swiss Machining Academy.

Now, in a multi-year partnership, SolidCAM is the exclusive CAM software Titan uses to support all his sponsored machines (including YCM, MCO, Matsura, and Sodik for Wire EDM).

Critically, Titan is redoing all his free training “building blocks,” which were previously based on a competitor’s software. Now, they are entirely built with SolidCAM, promising massive growth in education, especially in the US. Emil encouraged attendees to check out the huge Bombastic 2025 event in Dallas this November.

iMachining: The Music of Making Money

Emil reiterated a crucial fact: “A machine shop who doesn’t have iMachining is losing money every day“. He guarantees savings of 70% or more in cycle time and a fivefold increase in tool life.

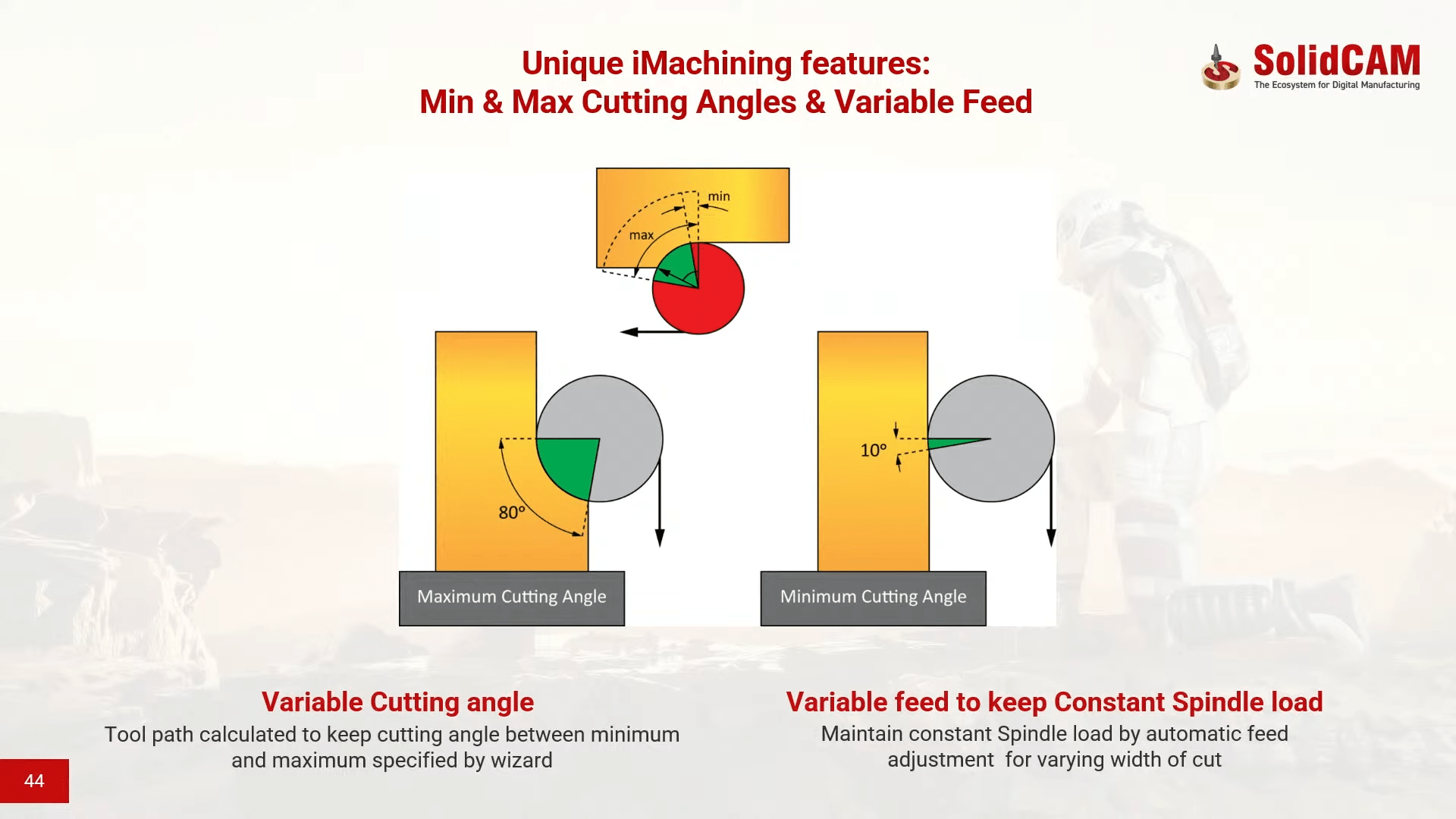

The secret sauce is the Technology Wizard. This is “a godsend to every manufacturer” because it eliminates the guessing game. The Wizard automatically calculates optimal feeds and speeds for every point in the toolpath. It factors in stock material, cutting tool geometry, and machine properties. The main principle is to guarantee a constant spindle load of around 30–40%. This is achieved by constantly adjusting the feed rate—slowing in corners and speeding up on straight lines.

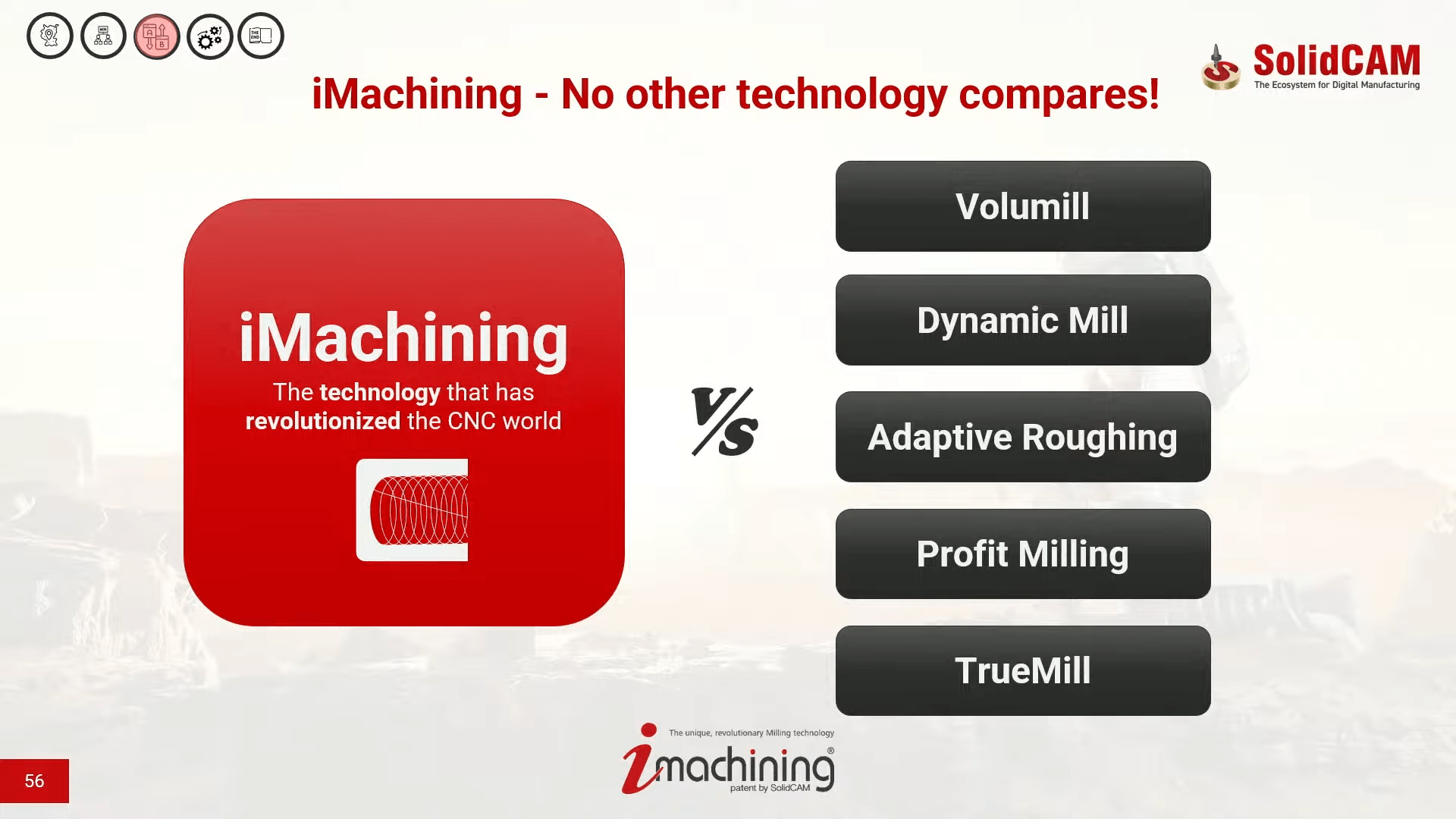

Emil stressed that the Wizard is our unique advantage. While competitors claim similar “fast milling” (like Volume Mill or Dynamic Mill), users are still “afraid to work very fast with it” because they lack the Wizard’s guarantee that the machine will not break.

iMachining really is protected, holding seven patents registered around the world. When an iMachining machine is cutting, Emil calls it “the music of making money”.

He also briefly introduced our new three-axis technology, Pro 3D HSR and HSM. It offers very fast toolpath computation, intelligent collision avoidance, and supports high-feed cutters for an excellent finish.

Regarding Milturn and Swiss, Emil shared a key internal decision. About 12 years ago, Michael Vineski, our Chief Product Officer, decided to stop relying on the post-processor to fix complex machine issues.

They reinvented the software’s core, ensuring all kinematics and controllers are handled inside the software. This is the difference between having the “best support” and having a competitor’s “wobbly” system. This architecture supports an unlimited number of channels and features the best MCOs (Machine Control Operations) for tasks like part transfers and retracts.

The Digital Ecosystem: Solid Shop

The final technical core value is our massive leap into Industry 4.0 with Solid Shop.

Emil first highlighted SolidCAM for Operators, which provides the full SolidCAM functionality without the SolidWorks CAD system.

This ensures synchronization and prevents crashes. It also removes the need for operators to constantly bother the CAM programmer for simple G-code or setup details. The system offers three customizable modes: Simulation Only, Editor Lite, and Full Editor, depending on how much trust the owner places in the operator.

The newly launched Solid Shop is the “digital hub for all CNC machine shops”. It provides complete shop floor digitization, which is essential for shops facing high competition and needing higher efficiency and data-driven decisi</strong>on making. Emil encouraged resellers to target their 22,000 existing SolidCAM customers first, as they already trust our product and support.

Modules Covering the Entire Shop Floor

The modules cover the entire shop floor workflow:

- Simco Editor and the incredibly fast, GPU-accelerated G-code Machine Simulator (up to five-axis). Preventing just one crash on a five-axis machine could pay for the entire system.

- Shop PDM (crucially, not SolidWorks PDM). This solves the common shop floor chaos of having “five versions of the G-code” lying around. It records the entire history of the G-code and every change made by the operator.

- DNC for machine communication.

- Monitoring to provide full, real-time data on every machine.

- AI to analyze the monitoring data and provide productivity suggestions.

- Integration with the Shop ERP or MES system for synchronization of orders and results.

Emil emphasized that Solid Shop is scalable and affordable. You don’t have to implement everything at once; you can start with G-code simulation or SolidCAM for Operator.

Technical Support, Learning, and AI Integration

He also highlighted the second key to success: technical and post-support. Emil announced the launch of the free SolidCAM Academy, an e-learning platform with hundreds of short 3–5 minute video lessons for the 2025 version.

These lessons were created by the product managers themselves.

He then introduced the SolidCAM Chatbot AI Assistant, powered by ChatGPT but trained on all SolidCAM user manuals, FAQs, and technical data. Emil joked that it is “more knowledgeable about SolidCAM than anybody here.”

This is just the beginning. We are in the final stages of integrating CloudNC CAM Assist for automatic CAM programming. Emil reminded the audience that AI alone is never enough—you still need HI + AI (Human Intelligence).

His strategic closing point was our Strength through Independence. While all our competitors have been acquired by conglomerates, Emil confirmed that they came to us first, and he said “no interest”. We will stay independent, ensuring we retain the agility and flexibility to serve our customers and partners first.

Natalie S.: Vision, Plan, and the Disciplined Execution

Following Emil S. is never easy. But Natalie Somekh, our CSO, brought incredible energy. She noted that standing on stage and seeing all the SolidCAMers gathered feels like family, no matter how much the company has grown.

The Formula for Success

Her message centered on the essential formula for success. Emil had the vision 40 years ago to make a global impact and help shops reach maximum productivity. But is vision enough? Natalie stressed that success is not luck; it’s a decision. Success requires Vision, Plan, and Execution. The vision is exciting, the planning is exciting, but “Execution could be hard. You wake up every day, you need to be disciplined”.

The 10% Market Vision

Natalie restated her personal, ambitious vision first shared in 2023: grabbing 10% market share from the global CAM market. To her, 10% represents being a game-changer for “tenth of thousands of more machine shops”. According to the latest SIM data report of 2025, we are currently at 4.2% market share, showing we have distance to travel, but the plan is sound.

The Six Core Pillars of the Plan

She detailed the six core pillars that form the “Plan” to reach that 10% goal:

- Partnerships: The critical path to the shop floor is through CNC manufacturers and their resellers; their recommendation is essential, complemented by cutting tool and probe manufacturers.

- Brand Awareness and Marketing: Our message must be loud and clear: “We are SolidCAM and we can be a game-changer for your shop floor”. We need to master digital algorithms to maximize our outreach.

- Enablement Processes: We must equip our field teams—technical, support, and sales—with the best tools, like the new SolidCAM Academy, to deliver maximum value.

- Strengthening Reseller Network: We are partners, and we must constantly ask how we can empower our valued resellers in every local market.

- Education: We must empower students—the “tomorrow’s CAM programmers”. She praised the work of , our Global Education Manager, and noted the importance of the Titans of CNC partnership in reaching hundreds of thousands of students.

- Product Innovation: We never stop, staying at the forefront of technology from three-axis to multi-channel Swiss, and now taking a major leap with Solid Shop. This pillar also encompasses the use of AI through the Chatbot, the integration of CloudNC CAM Assist, and using AI to turn monitoring data into actionable insights.

Confidence in Achieving the Goal

Natalie expressed her absolute confidence in reaching the 10% goal. We have 40 years of development experience. We never compromise on our easy-to-use, easy-to-learn environment. Our technical and post-processor support is world-class—the “car without wheels” metaphor shows support is essential; without it, the system is worthless. We are fully integrated with SolidWorks, the most loved and widely used CAD system in the world. Most importantly, we remain committed to staying independent.

Natalie turned the focus directly to the attendees, challenging them: “What is your SolidCAM vision?”. She wasn’t asking for dry sales goals, but the verbal, passionate visualization of their success in their local market.

The Winning Formula for Reseller Success

She concluded with the winning formula for maximum reseller success, insisting no one needs to “reinvent the wheel”:

- Dedicated SolidCAM Team: Non-negotiable. Dedicated teams are laser-focused, speak the language of machine shops, and act as solution providers and advisors.

- Customer Care: Being there at every step of the customer’s journey, ensuring they stay on subscription to receive the latest versions and the best support.

- Education Initiatives: Connecting to schools and training centers to empower the students who will become the next generation of SolidCAM users.

- Strategic Local Partnerships: While we work globally, local resellers must simultaneously connect with local CNC manufacturers, suppliers, and cutting tool companies.

- Marketing: Being the local voice for SolidCAM by using social media and content to promote the software.

- Business Planning and Commitment: Success is a decision. Partners must write business plans, set goals, measure results, and stay consistent. Natalie committed that SolidCAM will match every partner’s effort every step of the way.

Closing Thoughts

Day One closed with the powerful reminder that we are never alone; the SolidCAM team is “always out there with you on the field, next to the CNC machines”. The future of digital manufacturing is clear: it is SolidCAM and Solid Shop, and we can only achieve it together.

- SolidCAM World 2025 in Prague – DAY 1 - 24 October 2025

- PTC Gives 6 Months Free Access to Onshape Professional - 15 October 2025

- 3DEXCITE CEO Tom Acland on Building Meaningful Value with 3D Twins - 15 October 2025